Anwendungen für die Industrieautomatisierung

Simulink® ermöglicht es Herstellern von Industrieanlagen, ausführbare Spezifikationen in Form von Modellen zu erstellen, die klare Designvorgaben für verschiedene Entwicklungsteams liefern. Die nachfolgenden Beispielmodelle veranschaulichen Anwendungen in der Industrieautomatisierung.

Enthaltene Beispiele

Model and Control Robot Dynamics to Automate Virtual Assembly Line

Extends the Smart4i virtual commissioning applications to accommodate robot dynamics in the system framework to automate assembly line operation. This example models the digit twin of the Smart4i setup and controls the dynamics of robots in the assembly line, which helps develop a more realistic simulation environment. The virtual assembly line consists of four components: two robotic workcells, connected by a shuttle track and a conveyor belt. The first robot, Robot 1, is a Comau Racer V3 and places cups onto the shuttle. The second robot, Robot 2, is a Mitsubishi RV-4F and places balls in the cups. The shuttle track system consists of four shuttles which continuously move to Robot 1, then to Robot 2, followed by a slider. A slider then delivers those cups containing balls to a container. For a detailed system overview, see Automate Virtual Assembly Line with Two Robotic Workcells (Robotics System Toolbox).

- Seit R2024a

- Live Script öffnen

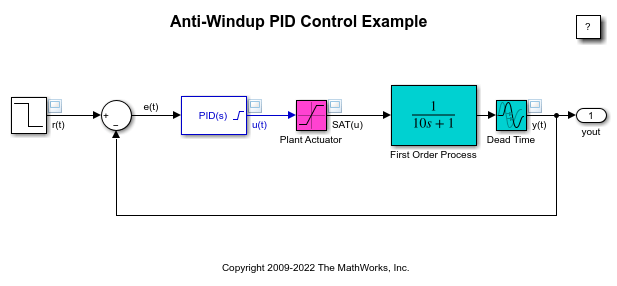

Anti-Windup-Regelung mithilfe eines PID Controller-Blocks

Dieses Beispiel zeigt, wie Sie Anti-Windup-Methoden verwenden können, um ein Integrations-Windup bei PID-Reglern zu vermeiden, wenn die Aktoren gesättigt sind. Der Block „PID Controller“ in Simulink® umfasst zwei integrierte Anti-Windup-Methoden, back-calculation und clamping sowie einen Trackingmodus für den Umgang mit komplexeren industriellen Szenarien. Der Block „PID Controller“ unterstützt mehrere Funktionen, die einen Umgang mit Steuerungs-Windup-Problemen in häufig auftretenden industriellen Szenarien ermöglichen.

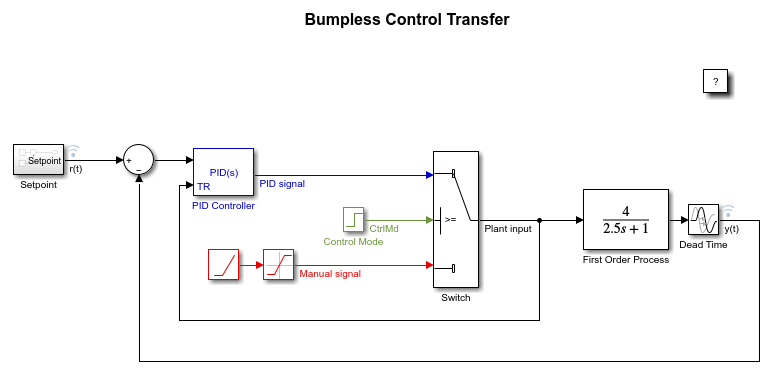

Bumpless Control Transfer Between Manual and PID Control

Achieve bumpless control transfer when switching from manual control to proportional integral derivative (PID) control. The model uses the PID Controller block in Simulink® to control a first-order process with dead-time.

Two Degree-of-Freedom PID Control for Setpoint Tracking

Regulate the speed of an electric motor using two degree-of-freedom PID control with set-point weighting. This model uses the PID Controller (2DOF) block. The model changes the setpoint values between 60 and 30 rpm. To convert the units to rad/s for use in the PID controller, the model uses a Signal Conversion block.

Job Scheduling and Resource Estimation for a Manufacturing Plant

Model a manufacturing plant. The plant consists of an assembly line that processes jobs based on a pre-determined schedule. This example walks you through a workflow for:

(SimEvents)

Shape Tracing Manipulator with Simulink 3D Animation

Model and visualize the shape tracing manipulator in the 3D environment.

- Seit R2025a

- Live Script öffnen

MATLAB Command

You clicked a link that corresponds to this MATLAB command:

Run the command by entering it in the MATLAB Command Window. Web browsers do not support MATLAB commands.

Website auswählen

Wählen Sie eine Website aus, um übersetzte Inhalte (sofern verfügbar) sowie lokale Veranstaltungen und Angebote anzuzeigen. Auf der Grundlage Ihres Standorts empfehlen wir Ihnen die folgende Auswahl: .

Sie können auch eine Website aus der folgenden Liste auswählen:

So erhalten Sie die bestmögliche Leistung auf der Website

Wählen Sie für die bestmögliche Website-Leistung die Website für China (auf Chinesisch oder Englisch). Andere landesspezifische Websites von MathWorks sind für Besuche von Ihrem Standort aus nicht optimiert.

Amerika

- América Latina (Español)

- Canada (English)

- United States (English)

Europa

- Belgium (English)

- Denmark (English)

- Deutschland (Deutsch)

- España (Español)

- Finland (English)

- France (Français)

- Ireland (English)

- Italia (Italiano)

- Luxembourg (English)

- Netherlands (English)

- Norway (English)

- Österreich (Deutsch)

- Portugal (English)

- Sweden (English)

- Switzerland

- United Kingdom (English)