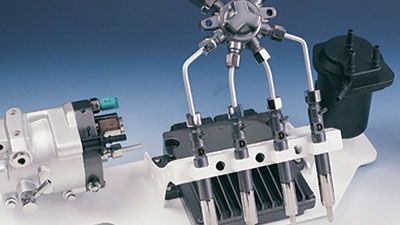

Powertrain

Using Model-Based Design, engineers design modern powertrain controllers that are easily adapted and calibrated to local markets worldwide and satisfy customer demand for excellent performance and high quality.

Design Powertrain Controllers and Generate Code to Meet Quality and Time-to-Market Demands

To develop modern powertrain control algorithms that meet vehicle-level requirements, engineers design and verify powertrain controllers that have over one million lines of code and are implemented on multiple vehicle control module architectures. They use MATLAB and Simulink products to:

- Design and test controller models using desktop simulation

- Verify functionality with physical hardware through rapid prototyping

- Generate production code

- Analyze generated or hand-written code using Polyspace code verifiers

Calibrate Powertrain Controllers on the Desktop and Reduce the Number of Prototypes

In modern powertrain controllers, thousands of parameters must be tuned to account for vehicle variations and local market requirements. Engineers use these parameters to make tradeoffs between steady-state and dynamic objectives such as fuel economy, torque, and emissions.

When electronic engine controllers were first introduced, they had far fewer parameters to tune, and calibration engineers relied on experience and intuition to make the tradeoffs. With the availability of more computational power and memory, the number of parameters to tune has grown into the thousands. To minimize the number of prototype vehicles necessary to calibrate modern conventional and alternative-technology vehicles, engineers collect dynamometer data to develop and analyze models and use technical computing capabilities to find the optimal solution in a complex space of variables.

SAE Analytical Calibration Panel Discussion: Cummins, International Truck, John Deere, GM

Presentations from OSU, Cummins, GM, International, John Deere, and The MathWorks