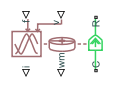

Piezo Rotary Actuator

Torque-speed characteristics of rotary piezoelectric traveling wave motor

Libraries:

Simscape /

Electrical /

Electromechanical /

Mechatronic Actuators

Description

The Piezo Rotary Actuator block represents the torque-speed characteristics of a piezoelectric traveling wave motor. The block represents the torque-speed relationship of the motor at a level that is suitable for system-level modeling. To simulate the motor, the block uses the following models:

Inertia and Friction Model for Unpowered Motor

The motor is unpowered when the physical signal input v is zero. This corresponds to applying zero RMS volts to the motor. In this scenario, the block models the motor using the following elements:

An inertia whose value is the Rotor inertia parameter value.

A friction whose characteristics are determined by the parameter values in the Motor-Off Friction tab.

The block uses a Simscape™ Rotational Friction block to model the friction component. For detailed information about the friction model, see the Rotational Friction block reference page.

Resonant Circuit Model for Powered Motor

When the motor is active, Piezo Rotary Actuator block represents the motor characteristics using the following equivalent circuit model.

In the preceding figure:

The AC voltage source represents the block's physical signal input of frequency f and magnitude v.

The resistor R provides the main electrical and mechanical damping term.

The inductor L represents the rotor vibration inertia.

The capacitor C represents the piezo crystal stiffness.

The capacitor Cp represents the phase capacitance. This is the electrical capacitance associated with each of the two motor phases.

The torque constant kt relates the RMS current i to the resulting mechanical torque.

The quadratic mechanical damping term, λωm2, shapes the torque-speed curve predominantly at speeds close to maximum RPM. ωm is the mechanical rotational speed.

The term represents the rotor inertia.

At model initialization, the block calculates the model parameters R, L, C, kt and λ to ensure that the steady-state torque-speed curve matches the values of the following user-specified parameter values:

Rated torque

Rated rotational speed

No-load maximum rotational speed

Maximum torque

These parameter values are defined for the Rated RMS voltage and Motor natural frequency (or rated frequency) parameter values.

The quadratic mechanical damping term produces a quadratic torque-speed curve. Piezoelectric motors torque-speed curves can typically be approximated more accurately using a quadratic function than a linear one because the torque-speed gradient becomes steeper as the motor approaches the maximum speed.

If the rotor inertia J is not specified on the datasheet, you can select a value that provides a good match to the quoted response time. The response time is often defined as the time for the rotor to reach maximum speed when starting from rest, under no-load conditions.

The quality factor that you specify using the Resonance quality factor parameter relates to the equivalent circuit model parameters as follows:

This term is not usually provided on a datasheet. You can calculate its value by matching the sensitivity of torque to driving frequency.

To reverse the motor direction of operation, make the physical signal input v negative.

Assumptions and Limitations

When the motor is powered, the model is valid only between zero and maximum speed, for the following reasons:

Datasheets do not provide information for operation outside of normal range.

Piezoelectric motors are not designed to operate in the powered braking and generating regions.

The block behaves as follows outside the valid operating region:

Below zero speed, the model maintains a constant torque that is the zero rpm torque value. The zero rpm torque value is the Maximum torque parameter value if the RMS input voltage equals the Rated RMS voltage parameter value, and the frequency input equals the Motor natural frequency parameter value.

Above maximum speed, the model produces the negative torque predicted by the equivalent circuit model, but limits the absolute value of the torque to the zero-speed maximum torque.

The torque-speed characteristics are most representative when operating the model close to the rated voltage and resonant frequency.

Ports

Input

Output

Conserving

Parameters

Extended Capabilities

Version History

Introduced in R2009a