Aircraft Environmental Control System

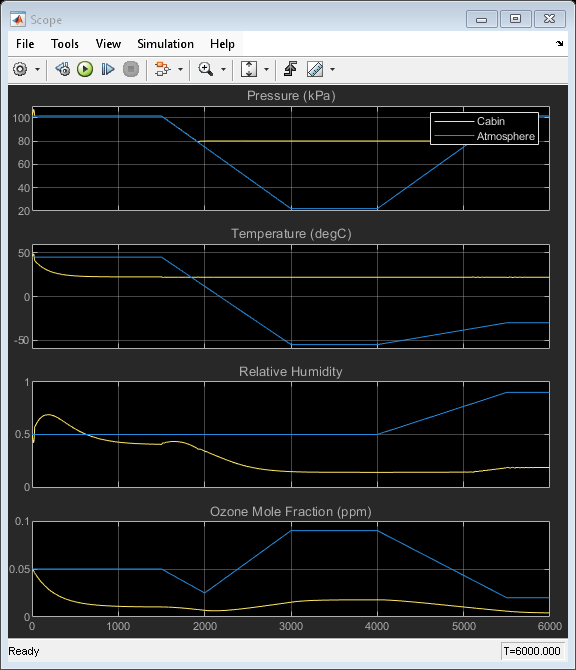

This example models an aircraft environmental control system (ECS) that regulates pressure, temperature, humidity, and ozone (O3) to maintain a comfortable and safe cabin environment. Cooling and dehumidification are provided by the air cycle machine (ACM), which operates as an inverse Brayton cycle to remove heat from pressurized hot engine bleed air. Some hot bleed air is mixed directly with the output of the ACM to adjust the temperature. Pressurization is maintained by the outflow valve in the cabin. This model simulates the ECS operating from a hot ground condition to a cold cruise condition and back to a cold ground condition.

Simple models of the compressor, turbine, and heat exchangers in the ACM are implemented as custom components based on the Simscape™ Foundation Moist Air library.

Model

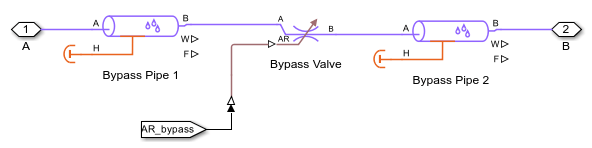

Bypass Flow Subsystem

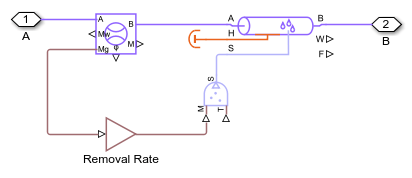

Catalytic Converter Subsystem

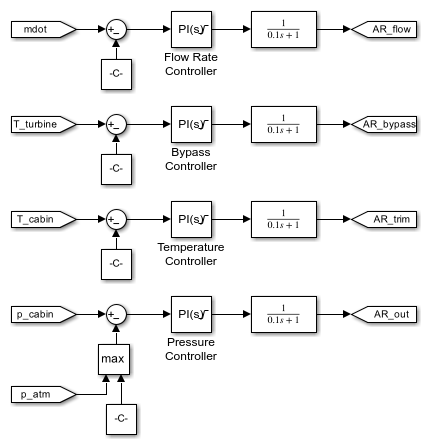

Controllers Subsystem

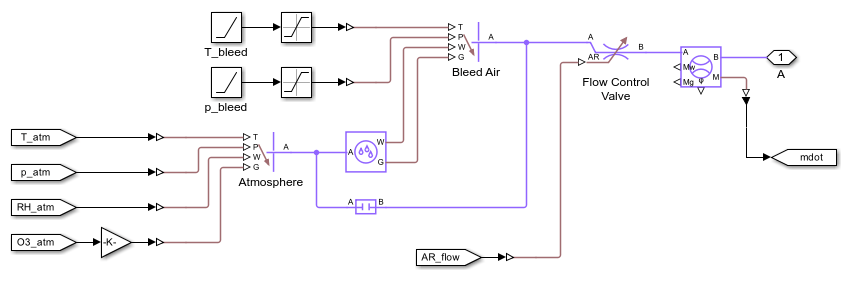

Engine Bleed Air Subsystem

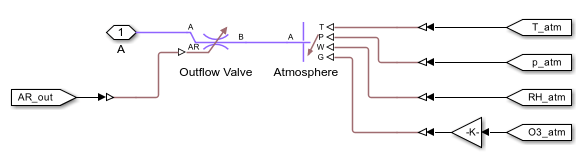

Outflow Subsystem

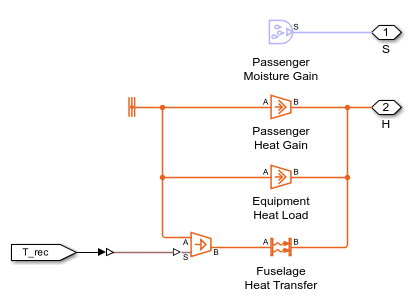

Thermal & Moisture Loads Subsystem

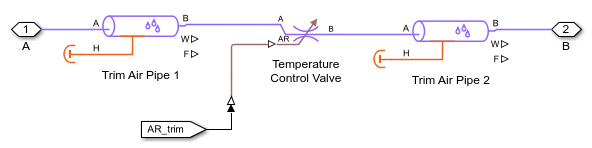

Trim Air Flow Subsystem

Simulation Results from Scopes

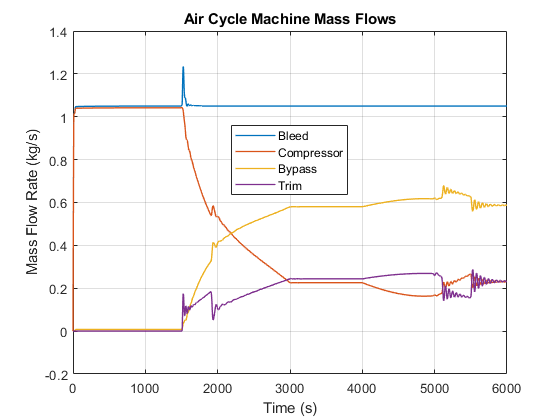

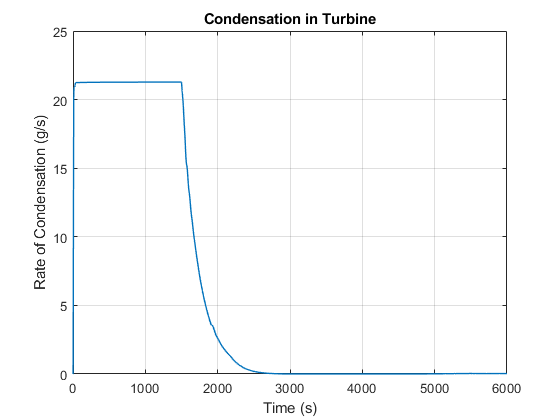

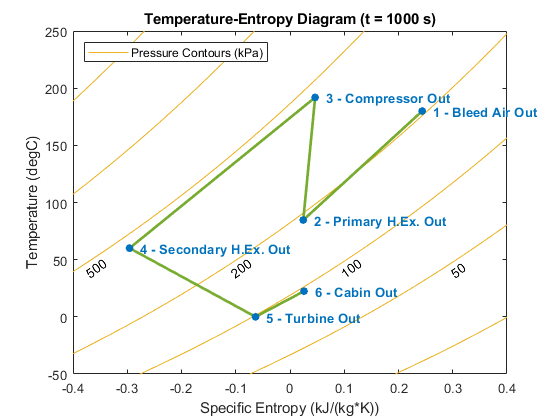

Simulation Results from Simscape Logging

This plot shows the effect of the valves that regulate the air flow through the system. As the external environment becomes cooler, some of the air flow bypasses the compressor and turbine to prevent the turbine outflow from becoming too cold. Furthermore, some hot engine bleed air is used as trim air to adjust the temperature of the air flow supplied to the cabin.

This plot shows the moisture removed from the hot humid air by the air cycle machine (ACM).

This plot shows thermodynamic states of the air flow in a temperature-entropy diagram when the air cycle machine (ACM) is cooling and dehumidifying the cabin. It is an inverse Brayton cycle that extracts work from the pressurized bleed air to cool the air flow below the ambient temperature.

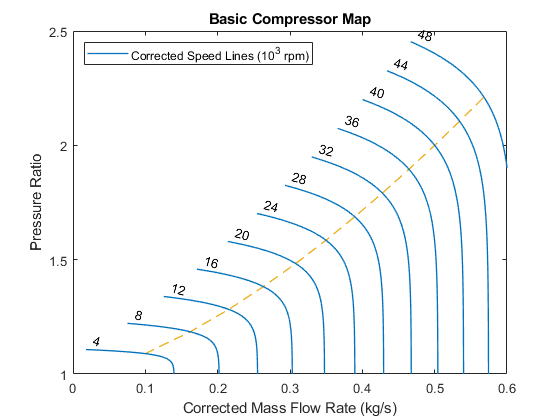

This plot shows a basic compressor map used by the air cycle machine (ACM) parameterized by 3 coefficients that control the shape and spacing of the corrected speed lines.