Moss Landing Verifies Ocean Color Data with MATLAB and Instrument Control Toolbox

“Instrument Control Toolbox solves many problems of general data acquisition for us.”

Challenge

Solution

Results

- Single environment for data analysis and acquisition

- Simplified data collection

- Adaptable procedures for data acquisition

In the late 1990s, NASA launched two ocean color satellites. These satellites measure light reflected out of the ocean, providing data to detect global warming, irregularities in the biological food chain, and other environmental problems.

Since the satellites degrade over time, their output must be continually checked for accuracy. To this end, the National Oceanic and Atmospheric Administration (NOAA) initiated a program that uses radiometers in the marine optical systems (MOS) to validate data from the satellites. These radiometers measure the color of light reflected out of sea water at several depths. Researchers at Moss Landing Marine Laboratories, funded by NOAA and NASA, then correlate the ocean color data from MOS with that from the satellites.

Moss Landing uses MATLAB® and Instrument Control Toolbox™ to collect and analyze their data and to calibrate the MOS instruments.

Challenge

The NOAA-NASA project requires that the MOS instruments equal or exceed the precision of the satellite sensors. To meet this requirement, Moss Landing must regularly monitor the instruments’ output and performance.

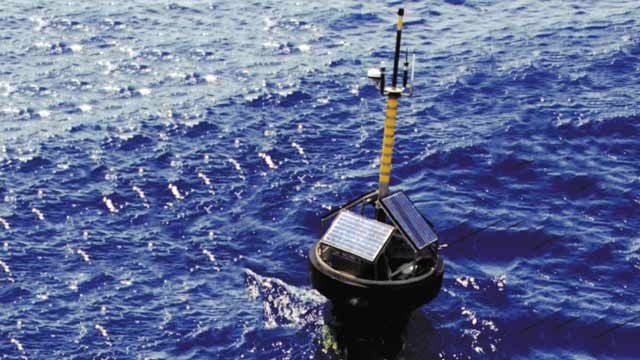

Moss Landing researchers use two MOS instruments. The first is deployed within a marine optical buoy (MOBY) moored near the Hawaiian island of Lanai. The second is installed aboard research vessels that travel the Pacific Ocean to obtain a wider sampling of ocean color characteristics.

Each instrument brings different data quality control challenges. Because the MOBY is continually exposed to sea water, both the buoy and its onboard instruments are prone to degradation. The researchers who operate the shipboard MOS must collect data while the boat is operating in eight-foot waves that cause refraction in the subsurface light field, resulting in noisy measurements.

At the beginning of the project, Moss Landing used C programs on an old VAX workstation to operate both MOS instruments. This solution was “a little stifling,” recalls Dr. William Broenkow, Moss Landing project leader: “We didn’t have access to a command-line interface on the VAX, so everything had to go through one program.” In addition, the VAX machine was heavy and cumbersome. The researchers needed a more flexible and portable solution.

Solution

Moss Landing uses MATLAB and Instrument Control Toolbox to control the MOS instruments from laptop computers.

The MOS instruments run on the Forth operating system. Broenkow and programmer Mike Feinholz wrote a library of functions based on Instrument Control Toolbox to send Forth commands to the MOS instruments to send and receive data. A TT7 microcomputer inside MOS interprets these functions and initiates the data collection. Analog/digital sensor output and spectral data are sent back through the serial port, where they are digitized, converted to scientific units, and sent to MATLAB for processing and analysis.

Moss Landing also uses MATLAB and Instrument Control Toolbox to deal with the problem of noisy data at sea. To ensure accurate results, the oceanographers take frequent measurements and average out the wave noise.

Moss Landing developed a GUI to simplify data collection. Surface irradiance is measured from a sensor mounted on the ship and from light collectors on MOS. For each collector, they take two dark scans and five light scans and select scan parameters using drop-down menus and editable text boxes in the MATLAB interface that they developed. They then use MATLAB functions to average out wave noise, perform calibration corrections, and plot the final data.

Being able to carry out the instrument control functions in the same environment as that used to view, process, and analyze the data provides a great deal of flexibility, says Broenkow: “If the parameters on the incoming data need to be changed, we can enter commands on the spot, without involving process delays from one computer to another.”

Results

Single environment for data analysis and acquisition. Having instrument control and data analysis functions in the same environment enables faster access to the data. Once the data is collected with Instrument Control Toolbox, it can be processed in MATLAB immediately.

Simplified data collection. Using MATLAB, the researchers can run complex sets of measurements automatically. “Using the serial and GPIB objects allows our programmer to apply his knowledge of file I/O to instrument control and data acquisition,” Broenkow says. “Since he already understands MATLAB object-oriented graphics programming, he has all the skills necessary to use Instrument Control Toolbox.”

Adaptable procedures for data acquisition. The MOS calibrations require exacting work using very stable light sources. “Working with Instrument Control Toolbox functions allows me the freedom to change data acquisition procedures quickly and simply by changing function calls on the MATLAB command line,” says Feinholz.