Specific Dissipation Heat Exchanger (TL)

Heat exchanger parameterized by specific dissipation data for systems with thermal liquid and controlled flows

Since R2024a

Libraries:

Simscape /

Fluids /

Heat Exchangers /

Thermal Liquid

Description

The Specific Dissipation Heat Exchanger (TL) block models the cooling and heating of fluids through conduction over a thin wall. The properties of a single-phase thermal liquid are defined on the Thermal Liquid tab. The second fluid is a controlled fluid, which is specified only by the user-defined parameters on the Controlled Fluid tab. It does not receive any properties from the domain fluid network. The heat exchange between the fluids is based on the thermal liquid sensible heat.

Heat Transfer Model

Heat transfer by the simple model is based on specific dissipation:

where:

ξ is specific dissipation, which is a function of the mass flow rates of the thermal and controlled liquids.

TIn,Th is the thermal liquid inlet temperature.

TIn,C is the controlled liquid inlet temperature.

The simple model is based on linear interpolation of user-provided tabulated data and does not capture individual features of the heat exchanger.

The fluid properties that the block uses in heat transfer calculations are the average between the value at the inlet and the value in the fluid volume.

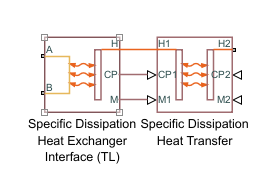

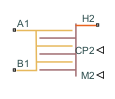

Composite Structure

The Heat Exchanger (TL) block is a composite of the Specific Dissipation Heat Exchanger Interface (TL) and Specific Dissipation Heat Transfer blocks: