Pressure-Compensated Pump (IL)

Constant-pressure, variable-displacement pump in an isothermal liquid network

Libraries:

Simscape /

Fluids /

Isothermal Liquid /

Pumps & Motors

Description

The Pressure-Compensated Pump (IL) block models a constant-pressure, variable-displacement pump in an isothermal liquid network. The pump displacement is controlled by the differential pressure, pcontrol, measured between ports X and Y. When this pressure exceeds the Set pressure differential, the fluid displacement is adjusted according to the pump Leakage and friction parameterization. The variable-displacement functionality occurs within the Pressure regulation range between the Maximum displacement, at pset, and the Minimum displacement, at pmax.

The fluid may move from port A to port B, called forward mode, or from port B to port A, called reverse mode. Pump mode operation occurs when there is a pressure gain in the direction of the flow. Motor mode operation occurs when there is a pressure drop in the direction of the flow.

Shaft rotation corresponds to the sign of the fluid volume moving through the pump. Positive fluid displacement corresponds to positive shaft rotation in forward mode. Negative fluid displacement corresponds to negative shaft angular velocity in forward mode.

Operation Modes

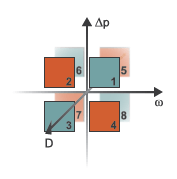

The block has eight modes of operation. The working mode depends on the pressure gain from port A to port B, Δp = pB – pA; the angular velocity, ω = ωR – ωC; and the fluid volumetric displacement, set by the pressure differential. The figure above maps these modes to the octants of a Δp-ω-D chart:

Mode 1, Forward Pump: Positive shaft angular velocity causes a pressure increase from port A to port B and flow from port A to port B.

Mode 2, Reverse Motor : Flow from port B to port A causes a pressure decrease from B to A and negative shaft angular velocity.

Mode 3, Reverse Pump: Negative shaft angular velocity causes a pressure increase from port B to port A and flow from B to A.

Mode 4, Forward Motor: Flow from port A to B causes a pressure decrease from A to B and positive shaft angular velocity.

Mode 5, Reverse Motor : Flow from port B to port A causes a pressure decrease from B to A and positive shaft angular velocity.

Mode 6, Forward Pump: Negative shaft angular velocity causes pressure increase from A to B and flow from A to B.

Mode 7, Forward Motor: Flow from port A to B causes a pressure decrease from A to B and negative shaft angular velocity.

Mode 8, Reverse Pump: Positive shaft angular velocity causes a pressure increase from port B to port A and flow from B to A.

The block has analytical, lookup table, and physical signal parameterizations. When using tabulated data or an input signal for parameterization, you can choose to characterize pump operation based on efficiency or losses.

The threshold parameters Pressure gain threshold for pump-motor transition, Angular velocity threshold for pump-motor transition, and Displacement threshold for pump-motor transition identify regions where numerically smoothed flow transition between the pump operational modes can occur. For the pressure and angular velocity thresholds, choose a transition region that provides some margin for the transition term, but which is small enough relative to the typical pump pressure gain and angular velocity so that it will not impact calculation results. For the displacement threshold, choose a threshold value that is smaller than the typical displacement volume during normal operation.

Analytical Leakage and Friction Parameterization

If you set Leakage and friction parameterization to

Analytical, the block calculates leakage and friction

from constant values for shaft velocity, pressure gain, and torque. The leakage flow

rate, which is correlated with the pressure differential over the pump, is

calculated as:

where:

Δpnom is pB – pA.

ρavg is the average fluid density.

K is the Hagen-Poiseuille coefficient for analytical loss,

where:

Dnom is the Nominal displacement.

ωnom is the Nominal shaft angular velocity.

ηnom is the Volumetric efficiency at nominal conditions.

Δpnom is the Nominal pressure gain.

The friction torque, which is related to the pump pressure differential, is calculated as:

where:

τ0 is the No-load torque.

k is the friction torque vs. pressure gain coefficient at nominal displacement, which is determined from the Mechanical efficiency at nominal conditions, ηm,nom:

τfr,nom is the friction torque at nominal conditions:

ω is the relative shaft angular velocity, or .

Tabulated Data Parameterizations

When using tabulated data for pump efficiencies or losses, you can provide data for one or more of the pump operational modes. The signs of the tabulated data determine the operational regime of the block. When data is provided for less than eight operational modes, the block calculates the complementing data for the other mode(s) by extending the given data into the remaining octants.

Tabulated data - volumetric and mechanical

efficiencies parameterizationThe leakage flow rate is calculated as:

where:

and ηv is the volumetric efficiency, which is interpolated from the user-provided tabulated data. The transition term, α, is

where:

Δp is pB – pA.

pthreshold is the Pressure gain threshold for pump-motor transition.

ω is ωR – ωC.

ωthreshold is the Angular velocity threshold for pump-motor transition.

The friction torque is calculated as:

where:

and ηm is the mechanical efficiency, which is interpolated from the user-provided tabulated data.

Tabulated data - volumetric and mechanical

losses parameterizationThe leakage flow rate is calculated as:

where qloss is interpolated from the Volumetric loss table, q_loss(dp,w,D) parameter, which is based on user-supplied data for pressure gain, shaft angular velocity, and fluid volumetric displacement.

The shaft friction torque is calculated as:

where τloss is interpolated from the Mechanical loss table, torque_loss(dp,w,D) parameter, which is based on user-supplied data for pressure gain, shaft angular velocity, and fluid volumetric displacement.

Input Signal Parameterization

When you select Input signal - volumetric and mechanical

efficiencies, ports EV and

EM are enabled. The internal leakage and shaft friction are

calculated in the same way as the Tabulated data - volumetric and

mechanical efficiencies parameterization, except that

ηv and

ηm are received directly at ports

EV and EM, respectively.

When you select Input signal - volumetric and mechanical

losses, ports LV and LM

are enabled. These ports receive leakage flow and friction torque as positive

physical signals. The leakage flow rate is calculated as:

where:

qLV is the leakage flow received at port LV.

pthresh is the Pressure gain threshold for pump-motor transition parameter.

The friction torque is calculated as:

where

τLM is the friction torque received at port LM.

ωthresh is the Angular velocity threshold for pump-motor transition parameter.

The volumetric and mechanical efficiencies range between the user-defined specified minimum and maximum values. Any values lower or higher than this range will take on the minimum and maximum specified values, respectively.

Pump Operation

The pump flow rate is:

where

The pump torque is:

where

The mechanical power delivered by the pump shaft is:

and the pump hydraulic power is:

To be notified if the block is operating beyond the supplied

tabulated data, set Check if operating beyond the range of supplied

tabulated data to Warning to receive a

warning if this occurs, or Error to stop the simulation

when this occurs. For parameterization by input signal for volumetric or mechanical

losses, you can be notified if the simulation surpasses operating modes with the

Check if operating beyond pump mode parameter.

You can also monitor pump functionality. Set Check if pressures are less

than pump minimum pressure to Warning to

receive a warning if this occurs, or Error to stop the

simulation when this occurs.

Displacement Parameterization

The linear parameterization of the pump displacement is:

where the normalized pressure, , is

where pmax is the sum of the Set pressure differential and the Pressure regulation range.

Displacement Dynamics

If displacement dynamics are modeled, a lag is introduced to the flow response to the modeled control pressure. pcontrol becomes the dynamic control pressure, pdyn; otherwise, pcontrol is the steady-state pressure. The instantaneous change in dynamic control pressure is calculated based on the Time constant, τ:

By default, the Displacement dynamics checkbox is not selected.

Numerically-Smoothed Pressure

You can maintain numerical robustness in your simulation by adjusting the Smoothing factor parameter. If the Smoothing factor parameter is nonzero, the block smoothly saturates the normalized control pressure between pset and pmax. For more information, see Numerical Smoothing.