Plate Heat Exchanger (TL-TL)

Libraries:

Simscape /

Fluids /

Heat Exchangers /

Thermal Liquid

Description

The Plate Heat Exchanger (TL-TL) block models a plate heat exchanger between two thermal liquid networks. The block models the heat transfer between the two thermal liquids based on the effectiveness-NTU method. Heat transfer can occur in either direction between the two fluids.

The block uses the Effectiveness-NTU (E-NTU) method to model heat transfer through the shared plate walls. You can also account for heat transfer through the plate itself by selecting the Enable plate thermal resistance parameter. The block models fouling on the exchanger walls, which increases thermal resistance and reduces the heat exchange between the two fluids.

Plate Heat Exchanger Geometry

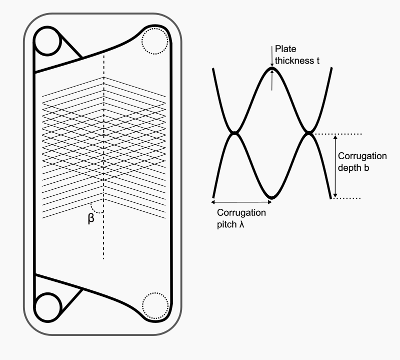

Plate heat exchangers consist of a series of clamped-together plates. Each plate has portholes for the fluid to flow through and gaskets around the portholes and the plate sides to contain the liquid. The gasket pattern alternates between the plates so that on each side of the plate, one fluid flows across the plate while the other fluid flows through it. This results in alternating layers of hot and cold fluid. This figure shows a section of counter-flow in a plate heat exchanger.

This figure shows an individual plate and a cross-section of two adjacent plates. In the individual plate image, the thick lines represent the gaskets and the dotted lines represent the plate corrugation. The block assumes that the flow channel gap between the plates equals the corrugation depth, b.

On this plate, one fluid flows from the top-right port hole across the plate to the bottom-right port hole. The other fluid flows through the gasket on the two left-side portholes and not touch the plate on this side. The plate corrugation patterns increase structural stiffness, surface area, and turbulence.

Because fluid flows along both sides of each plate, the total fluid volume is

where:

Np is the value of the Number of plates parameter.

Lp is the value of the Plate length parameter.

Wp is the value of the Plate width parameter.

b is the value of the Spacing between plates parameter.

The volume of each fluid is half of the total volume. The flow cross-sectional area, S, for each fluid is

The total projected surface area of the plates, assuming no corrugation, is

Each fluid has half of the total heat transfer surface area

where the area enlargement factor, ϕ, accounts for the increased surface area due to the corrugation

The hydraulic diameter for each fluid is

Effectiveness-NTU Heat Transfer

The convective heat transfer between the fluids is

where:

CMin is the lesser of the heat capacity rates of the two fluids. The heat capacity rate is the product of the fluid specific heat, cp, and the fluid mass flow rate. CMin is always positive.

TIn,TL1 is the zone inlet temperature of the thermal liquid 1.

TIn,TL2 is the zone inlet temperature of the thermal liquid 2.

ε is the heat exchanger effectiveness.

Effectiveness is a function of the heat capacity rate and the number of transfer units, NTU, and varies based on the heat exchanger flow arrangement. NTU is

where:

R is the total thermal resistance between the two flows due to convection, conduction, and any fouling on the plates:

where:

U is the convective heat transfer coefficient of the respective thermal liquid.

F is the value of the Fouling factor parameter on the thermal liquid 1 or 2 side.

RW is the thermal resistance through the plates. If you select Enable plate thermal resistance, where t is the value of the Plate thickness parameter and kp is the value of the Plate thermal conductivity parameter.

If you clear the Enable plate thermal resistance check box, RW = 0.

The fluid properties that the block uses in heat transfer calculations are the average between the value at the inlet and the value in the fluid volume.

The heat exchanger effectiveness varies according to the flow configuration. The effectiveness is for all flow arrangements.

When Flow arrangement is Parallel

flow

When Flow arrangement is Counter

flow

CR is the ratio between the heat capacity rates of the two fluids:

Conductive Heat Transfer

The conductive heat transfer in a zone is

where:

Tout,TL1 is the zone outlet temperature of the thermal liquid 1.

Tout,TL2 is the zone outlet temperature of the thermal liquid 2.

Rcond is the total conductive thermal resistance between the two flows,

where:

AW is the wall surface area.

k is the thermal conductivity of each fluid.

DH is the hydraulic diameter.

The total heat transfer is the sum of the convective and conductive heat transfer. The conductive heat transfer is negligible compared to the convective heat transfer. When the flow rate is zero, the convective heat transfer is also zero. However, because heat transfer from convection and conduction operate independently of each other, there is still conductive heat transfer even when the convective heat transfer is zero.

Pressure Loss

For both fluids and pressure loss parameterizations, the pressure loss between each port and the internal node is

where:

ṁA is the mass flow rate through port A1 or A2 when the block calculates the values for the thermal liquid 1 and thermal liquid 2 networks, respectively.

ṁB is the mass flow rate through port B1 or B2, when the block calculates the values for the thermal liquid 1 and thermal liquid 2 networks, respectively.

ρ is the fluid density.

ξports is the value of the Loss coefficient for inlet and outlet manifolds and ports parameter.

Sport,A is the value of the Cross-sectional area at port A1 or Cross-sectional area at port A2 parameter, when the block calculates the values for the thermal liquid 1 and thermal liquid 2 networks, respectively.

Sport,B is the value of the Cross-sectional area at port B1 or Cross-sectional area at port B2 parameter, when the block calculates the values for the thermal liquid 1 and thermal liquid 2 networks, respectively.

When the Pressure loss model parameter is

Friction factor, you use the Darcy friction

factor for flow between corrugated plates parameter to specify a

single constant friction factor for the fluid.

fDarcy is the value of the

Darcy friction factor for flow between corrugated plates

parameter.

When the Pressure loss model parameter is

Correlation for flow between corrugated plates, the

block calculates the Darcy friction factor based on the plate geometry data and

Reynolds number from [3].

The Reynolds number is where μ is the dynamic viscosity. When the Reynolds number is between 200 and 1000,

When the Reynolds number is greater than 2000,

The block uses a smooth cubic transition between these regions and for Reynolds numbers between 1000 and 2000. For Reynolds numbers below 200, the block calculates fDarcy from a laminar friction constant that ensures numerical robustness as the flow goes to 0.

Heat Transfer Coefficient

The heat transfer coefficient, U, is

where k is the fluid thermal conductivity. The heat transfer calculations depend on the value of the Heat transfer coefficient model parameter.

When Heat transfer coefficient model is

Colburn equation, the block calculates the heat

transfer coefficient from data by using the Colburn correlation

coefficients.

The Nusselt number is

where a, b, and c are the first, second, and third elements in the Coefficients [a, b, c] for a*Re^b*Pr^c parameter and Pr is the Prandtl number.

When Heat transfer coefficient model is

Correlation for flow between corrugated plates,

the block calculates the heat transfer coefficient based on the plate geometry

data. The Nusselt number from [3] is

where:

c1, c2, and c3 are the first, second, and third elements in the Coefficients for Martin correlation parameter.

Pr is the Prandtl number.

Plate Thermal Mass

If you select Enable plate thermal mass, the block models the heat exchanger plate thermal mass, which introduces a delay in the plate's transient response to changes in temperature or heat flux. If you model thermal mass, the plate stores heat in its bounds. This heat storage slows the transition between steady states so that a thermal perturbation on one side does not immediately manifest on the other side. The lag persists until the heat flow rates from the two sides balance.

If you select Enable plate thermal mass, the wall energy conservation is

where:

Mplate is the mass of the plates, which the block calculates from the plate geometry parameters and the Plate density parameter.

cp,plate is the value of the Plate specific heat parameter.

Tplate is the effective plate temperature. The block uses this value to model the transient response. You cannot measure this value.

The heat transfer to each fluid is

where:

Tin is the fluid inlet temperature on each side.

C is the heat capacity rate for each fluid.

The number of heat transfer units between the fluid and the plate on each side is

where A is the total plate surface area and U is the heat transfer coefficient.

Conservation Equations

The total mass accumulation rate for both thermal liquids is

where i is the mass flow rate of the fluid through a port i.

The energy conservation equations are

where ϕi is the energy flow rate at a port i.

The heat transferred to or from one thermal liquid, Q, equals the heat transferred from or to the other thermal liquid.

Ports

Conserving

Parameters

References

[1] Shah, Ramesh K., and Dusan P. Sekulic. Fundamentals of heat exchanger design. John Wiley & Sons, 2003.

[2] Longo, Giovanni A., Giulia Righetti, and Claudio Zilio. "A new computational procedure for refrigerant condensation inside herringbone-type Brazed Plate Heat Exchangers." International Journal of Heat and Mass Transfer 82 (2015): 530-536.

[3] Martin, Holger. "A theoretical approach to predict the performance of chevron-type plate heat exchangers." Chemical Engineering and Processing: Process Intensification 35.4 (1996): 301-310.