Implement Pipelining in Simulink

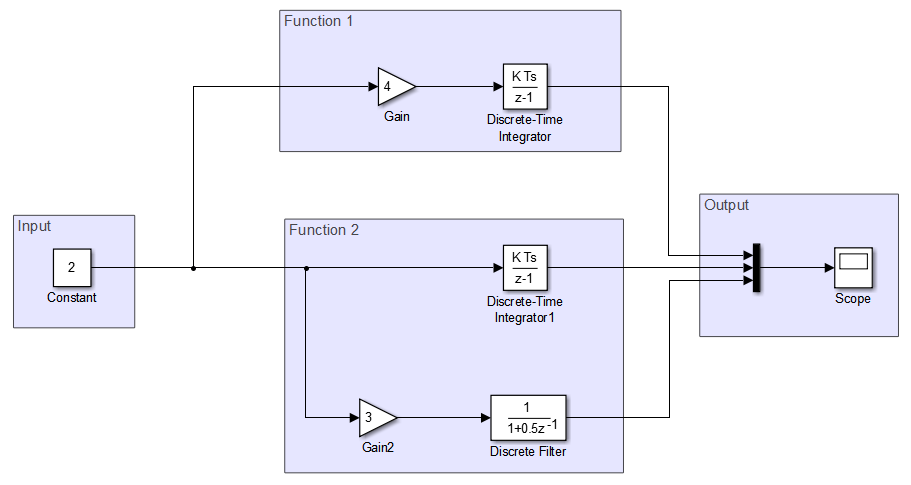

This example shows how to implement pipelining for a system represented in a Simulink® model. The ex_task_parallelism_initial model consists of an input, functional components applied to the same input, and a concatenated output. This example shows how to break up data dependencies between the tasks so that they can run completely in parallel. For more information on pipelining, see Types of Parallelism.

Set up this model for concurrent execution. To see the completed model, open ex_pipelining_top.

Configure Model for Concurrent Execution

Open the

ex_task_parallelism_initialmodel.Convert areas in this model to referenced models. Use the same referenced model to replace each of the functional components that process the input.

Set Model Configuration Parameters

Click Configure Tasks. In the Concurrent Execution dialog box, in the right pane, select the Enable explicit model partitioning for concurrent behavior check box. With explicit partitioning, you can partition your model manually.

On the Modeling tab, click Model Settings.

Select Solver, set Type to

Fixed-step, and click Apply.On the Solver pane, expand Solver details. Check that Periodic sample time constraint is set to

Unconstrained. Under Tasking and sample time options, select Allow tasks to execute concurrently on target.Select Code Generation > Interface > Advanced parameters. Clear the MAT-file logging check box.

Partition Model Using Explicit Partitioning

Partition the top model.

In the Concurrent Execution tree, under Tasks and Mapping, select CPU. Click Add task three times to add three new tasks.

Map Blocks to Tasks

In the Concurrent Execution tree, select Tasks and Mapping. On the Map block to tasks pane:

Under Block: Input, click

select taskand selectPeriodic: Task.Under Block: Function 1, select

Periodic: Task1.Under Block: Function 2, select

Periodic: Task2.Under Block: Output, select

Periodic: Task.

This action maps your partitions to the tasks you created. The Input and Output model blocks are on one task. Each functional component is assigned a separate task.

Finalize Model

Close the Concurrent Execution dialog box.

Share Configuration with Referenced Models

Apply configuration parameters to all referenced models.

Initialize Data Dictionary to Store Configuration Set

Create a

Simulink.data.dictionary.Entryobject that represents the configuration set, which is an entry in the dictionary. For this example, suppose the name of the dictionary ismyData.slddand the name of theSimulink.ConfigSetobject ismyConfigs.Store a copy of the target

Simulink.ConfigSetobject in a temporary variable.Save changes made to the dictionary.

Set Up Configuration Reference

Create a freestanding configuration set in the base workspace by copying the active configuration set of the model.

Create a separate configuration reference for the top model and each reference model. To point the reference to your freestanding configuration, set the

SourceNameproperty tofreeConfigSet, the variable that represents your configuration.Attach the configuration reference to each model by using the

ConfigSetRefobject. To use the configuration reference in the model, activate it for each model.

For more information, see Share a Configuration with Multiple Models, Automate Model Configuration by Using a Script, and Make Changes to Configuration Set Stored in Dictionary.

Update your model to see the tasks mapped to individual model blocks.

Notice that delays are introduced between different tasks, indicated by the z-1 badge. Introducing these delays may cause different model outputs in Simulink. Ensure that your model has an expected output on simulating the parallelized model.